Conveyors are often one of the most overlooked components within a more extensive snack food, bakery processing, or packaging line. Not taking the time to research before selecting the best conveyor for your application can lead to a line failure and a reduction of throughput, ultimately hurting your bottom line.

As you begin the due diligence on the conveyor options best for your line, utilize these four questions to help guide your research:

- What sanitary requirements are critical for your application?

- How will your products be transferred on and off the conveyor?

- What are the product attributes? This is key in selecting the correct belt for the conveyor.

- Who will be performing maintenance on the conveyors?

Sanitary design

Building a proper sanitary conveyor begins with understanding the level of sanitation required in your application. Knowing the level required can make a big difference in the conveyor needed. Conveyors can often be labeled as sanitary and/or stainless steel, but what is the difference between the two when not used in conjunction? Understanding the difference between sanitary conveyors and stainless steel models is critical in designing your conveyor solution.

Sanitary and stainless steel are often used together but don’t necessarily coexist in every conveyor. The majority of food processing conveyors are stainless steel. However, to be sanitary stainless steel, there needs to be access inside and outside the conveyor to ensure an appropriate level of sanitation.

The type of product being moved and where that product is on the processing line will also dictate the level of conveyor sanitation requirements. Identifying where the conveyor will be located along the food processing/packaging line is also essential in selecting the right platform.

For applications downstream in processing where the conveyor is moving sealed and packaged food, the conveyor might not need to be as hygienic as those carrying raw food and ingredients. These downstream conveyors often accumulate corrugated dust from the cardboard packaging, which can be cleaned by washing or simply wiping down the conveyor. This conveyor is still sanitary in design, but a more robust sanitary platform is rare for this application.

On the other hand, if the conveyor is located upstream and moving raw food, that platform will need to be completely disassembled and cleaned with appropriate cleaning agents. Both conveyors are sanitary, but the one on the processing side needs to be more robust in sanitary attributes than the one moving just packaged food.

A better understanding of the relationship between different styles of sanitary conveyors and how they are designed to work within specific applications will ensure the conveyance meets your production objectives and hygienic goals.

Product transfers

After identifying and matching up the right sanitary conveyor system for your application, product transfers, which refer to products moving onto and off the conveyor, are the next aspect to consider. Typically, when products (notably smaller snack foods and baked goods) are transferred from one line operation to another, you have the most significant risk of product damage. Minimizing that risk involves understanding the equipment interface and how the products will be presented to the conveyor for transfer.

Questions to consider are knowing the output rate, the products’ size and shape, the product orientation specific to individual conveyors, and next-step processes. Once this information is known, the right technology can be applied to achieve successful transfers without losing the orientation, spacing, or product location.

Belt technology

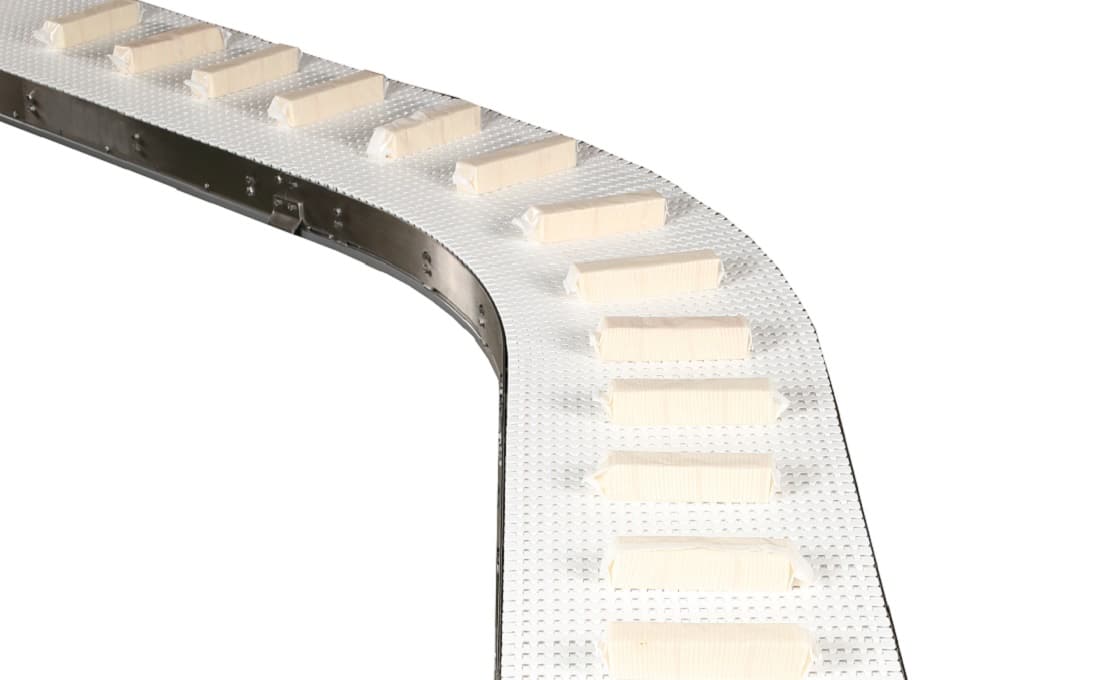

The main belts used in snack food and bakery processing and packaging applications are plastic chain and smooth flat belts. When handling warm bakery goods, a good option is plastic chain belts, which are ideal for high-temperature applications while also allowing air to flow through the conveyor to facilitate cooling. These belts are cut-resistant, easy to clean, and can twist around existing machinery. Smooth flat belts feature a seamless design with no supporting rods. These belts are ideal for a variety of snack food and bakery applications. This design enables the belt to be lifted for quick and easy cleaning.

Some applications call for products to travel up an incline or down a decline. In these instances, you need to factor in the coefficient of friction of the conveyor belt material and the coefficient of friction of the product being conveyed. Balancing these forces will determine whether you can convey the product on an incline or a decline, ultimately steering you to the right belt for your specific application. Belt technology is advancing rapidly with new materials and new manufacturing techniques that allow a wide range of belt textures and surfaces. Reputable conveyor suppliers will work with you to ensure your application’s proper belt choices.

Proper maintenance

Conveyors can run for a long time with general maintenance, however, frontline workers should know the warning signs of a looming problem, such as recognizing a frayed belt, belt slippage, or hearing unfamiliar noises.

From an operational standpoint, belt tracking is one of the biggest problems that can shut down a conveyor. If a belt isn’t tracking correctly, it will run along the edge of the conveyor frame and become frayed. Inspect the edges of the belt for fraying or signs of wear; these symptoms indicate that the belt isn’t tracking properly. If possible, carefully touch the tail plate to check for warmth; heat is often a symptom of bearing wear/failure or a belt tracking issue.

When conveyors need your attention, having a bench stock with the right parts on hand can go a long way toward minimizing downtime. Without a bench stock, receiving a replacement part may take two or more days, and that delay affects production. Your conveyor supplier should be able to provide you with a list of common replacement parts to keep in stock, such as pulleys, belts, drive belts, and other components, as well as provide training to make necessary repairs. They can also set you up with a preventive maintenance program to provide service at regularly scheduled intervals.

Conclusion

Food manufacturers are producing more products and SKUs than ever before. This means their conveyor systems need the flexibility to handle different product lines while designed for fast cleaning to minimize downtime. Selecting the right conveyor built with the required attributes to succeed in your application is essential to achieving your targeted production goals. Don’t take conveyors for granted. Doing the work upfront will keep the product moving smoothly for years.

This article was written by Dorner’s V.P. of Sales for Precision Conveyance John Kuhnz. This article was featured in Snack Food & Wholesale Bakery.